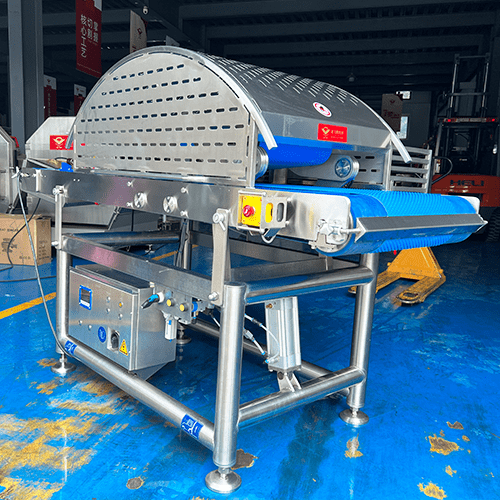

Horizontal Meat slicer

XFP-380

introduction:

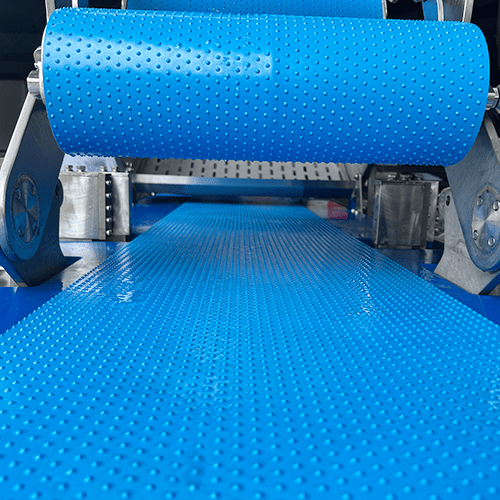

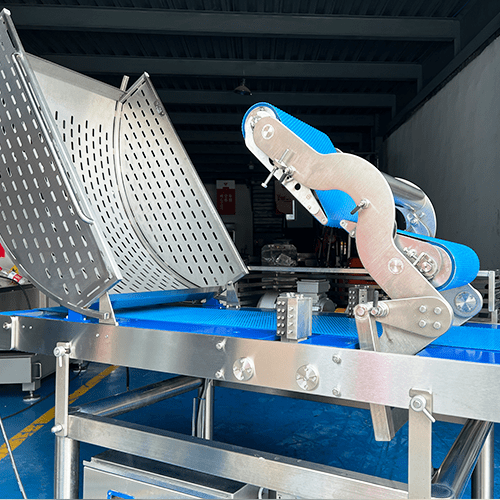

- This machine adopts double floating belt conveying, which has strong adaptability to raw materials and has a wide range of cutting, which can meet the cutting needs of different products and different sizes of customers to the greatest extent;

- Horizontal conveying can realize continuous production with other equipment.

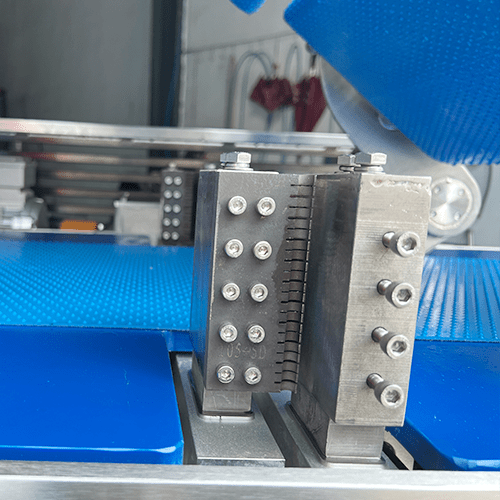

- Stainless steel double-edged blade, mirror surface treatment, reduce friction, improve cutting quality and long service life;

- Adjustable cutting thickness; high efficiency and high cutting precision;

- Pneumatic lifting, easy adjustment, saving time and effort;

- The self-adaptive blades tensioning system avoids the tensioning error caused by different sizes of blades and is easy to replace;

- The conveyor belt is driven by electric drum, which is safe and reliable;

- The conveyor belt can be easily disassembled, and the sanitary cleaning is convenient and thorough;

- The shield is equipped with a safety switch, and the whole machine is made of stainless steel and FDA-compliant non-metallic materials.

- It is mainly used for thin slice processing of deboned fresh beef, mutton, pork, chicken, seafood, cooked products, etc. It can also be used for slicing processing of block vegetables and other products. The finished products are cut cleanly without water loss;

Technical Features:

| Material | SUS 304SS |

| Dimension | 2180*1155*1480mm |

| Conveyor Belt Width | 380mm |

| Max. Feeding Size | 350(W)*100(H)mm |

| Conveyor Speed | 3-15m/min Frequency control |

| Slicing Thickness | ≥4mm customize |

| Slciing Temperature | ≥-2℃ |

| Voltage | 380V,50HZ |

| Power | 2KW |

| Weight | 270kg |