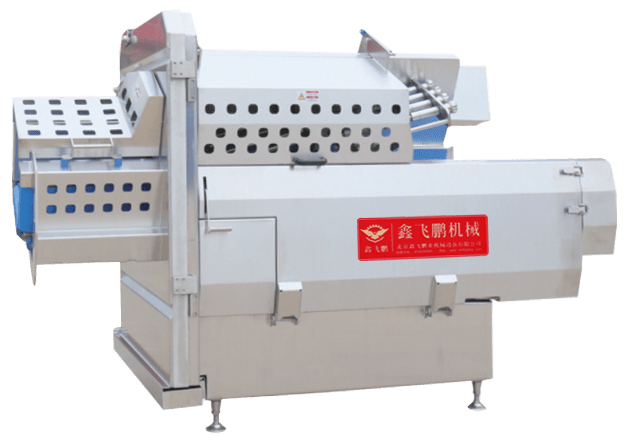

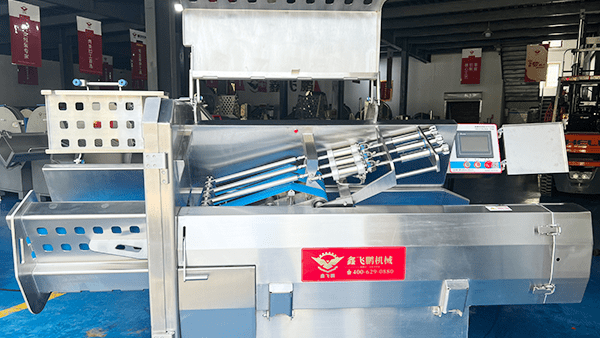

XFP-280K/360K continuous Portion Slicer & Chop Cutter

introduction:

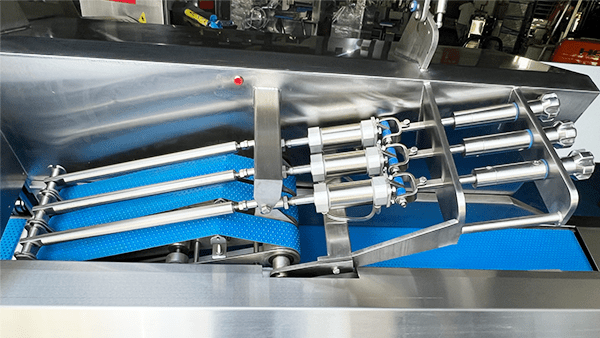

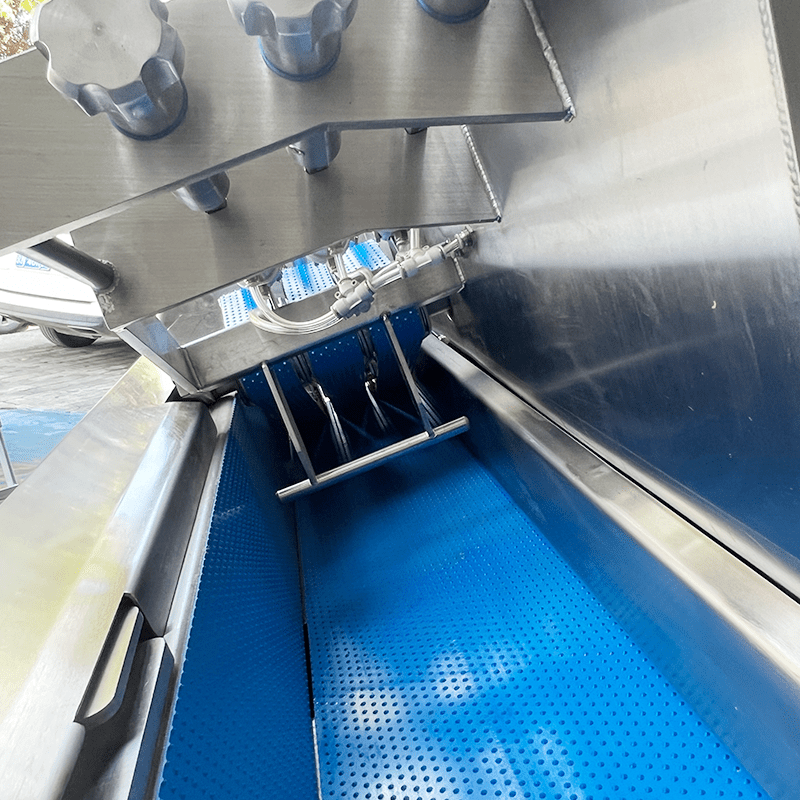

- V-belt continuous feeding method can make the raw material automatically fixed firmly on the feeding belt and the product is stable during cutting.

- The pressing method is that the length of the front pressing material is 150mm, so that no matter how high the pressing belt is lifted, it can always be parallel to the raw material.

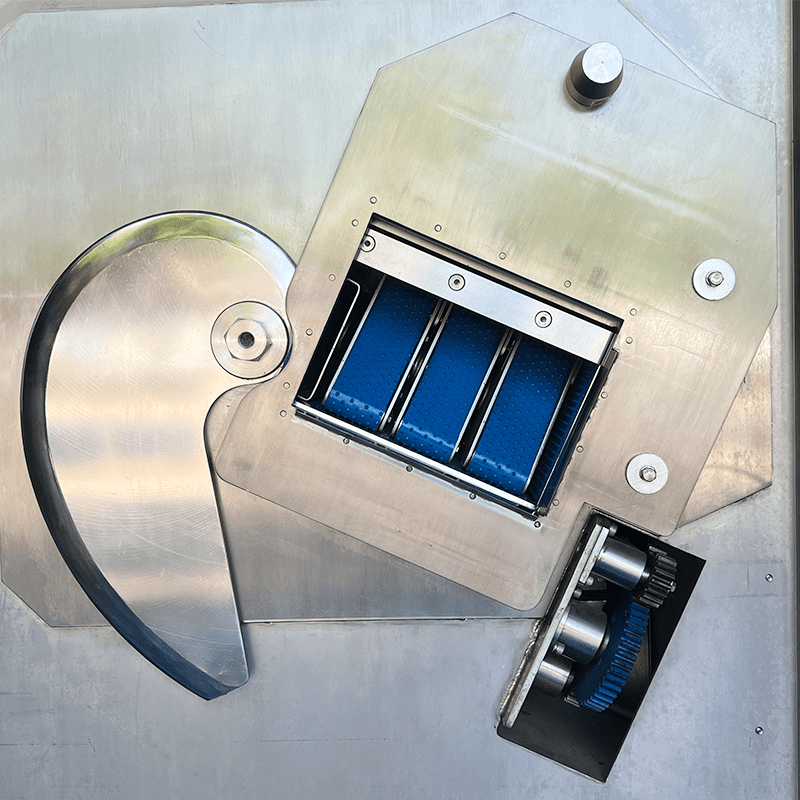

- The knife shaft part of the equipment adopts an advanced dynamic balance structure, which can make the equipment not shake when the knife speed reaches the maximum speed.

Control & Operation:

- This machine adopts frequency converter to control the drive motor;

- PLC touch screen

Performance:

- Cutter drive- Driven by a single motor, controlled by a frequency converter, and the cutting speed is adjusted according to the material;

- Material conveying part ——Driven by a servo motor, the conveying speed can be adjusted freely within a certain range according to the demand;

- Application- Meat, bone, slices, strips, blocks, shreds, to meet high-yield needs.

Technical Features:

| Model | XFP-280K | XFP-360K |

|---|---|---|

| Dimension | 2490*1090*1440mm | 2600*1300*1700mm |

| Feeding Bin Size | 280(w)*100(h)mm | 360(w)*190(h)mm |

| Slicing Speed | 120-290 slices/min | 160-320 slices/min |

| Slicing Thickness | 1-50mm adjustable | 1-50mm adjustable |

| Slicing Temperature | -8℃ - 0℃ | -8℃ - 0℃ |

| Recommend Slice Temp. | -4℃ - -3℃ | -4℃ - -3℃ |

| Power | 5.5KW | 7KW |

| Voltage | 380V,50HZ | 380V,50HZ |

| Weight | 1200kg | 1600kg |