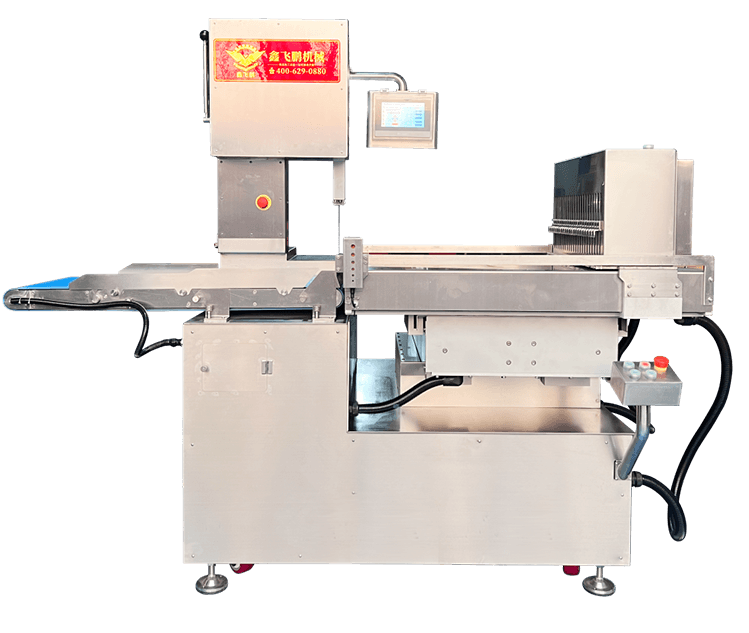

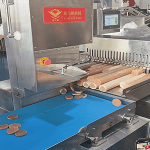

Fully-Automatic Bandsaw

XFP-6580

introduction:

- The whole machine is made of stainless steel SUS304, which is sturdy and durable, with a protective cover safety device, ultra-high waterproof design, and can be quickly washed;

- It can work for a long time to ensure the hygiene of the meat and the cutting surface is smooth;

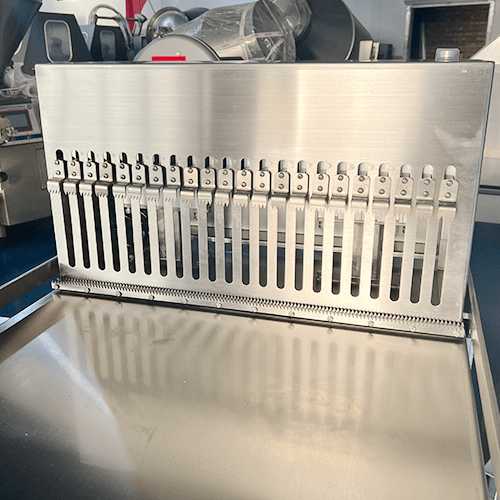

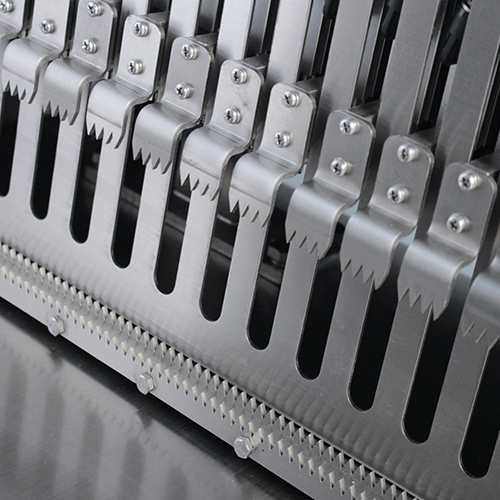

- Fixed the entire row of needle grippers to ensure stable feeding and precise portioning and cutting;

- Saw blades pressure tensioning device, easy to adjust and install;

- The design of bilateral driving wheels prevents the saw blades from falling off;

- High-precision design, the main and auxiliary wheel drive shock absorption can reach 0.01mm, which can make the cutting effect better, waste less, and use cost lower;

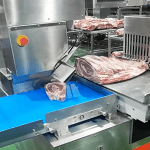

- The processing temperature can be as low as -30℃

- Touch-type intelligent operation panel, 5 sets of slicing memory can be set, and cutting speed can be customized;

- Thickness adjustment adopts servo motor to set thickness with high precision;

- Machine use: Cut frozen meat, bone-in meat and fish products according to the set thickness.

Technical Features:

| Material | 304 Stainless steel |

| Dimension | 1690×2220×1900mm |

| Loading Table Size | 650×800 mm |

| Loading material height | Max.150 mm |

| Cutting accuracy | 0.1mm |

| Adjustable Slicing Thickness | Max.200mm |

| Max Saw Blade Speed | 38 m/s |

| Saw Blade Size | 3430×16×0.56×4T |

| Power | 3phase 380V |

| Voltage | 3.5 KW |

| Weight | 1200 KG |

| Air Pressure Requirements | 0.4 mpa |

| Air volume requirements | 10 L/min |

| Slicing Speed | 10 Times/min |