XFP-430-2D (2 Dimensions) Frozen Meat Dicer (Continuous Feeding)

introduction:

- Four independent upper pressing conveyor belts, each belt pressing force adopts mechanical and pneumatic cooperation.

- PLC touch screen intelligent control can effectively save labor. Two feeding modes are optional: step and continuous feeding with adjustable speed.

- The feeding structure adopts the upper and lower pressing feeding belts driven by a servo drive. The feeding speed is precise and can be adjusted arbitrarily from 5-100mm, which realizes continuous feeding and cutting. The front end can be equipped with a slicer with a conveying structure. To the feeding belt of the machine, it can realize automatic production.

Control & Operation:

- This machine adopts frequency converter to control the drive motor;

- PLC touch screen

Performance:

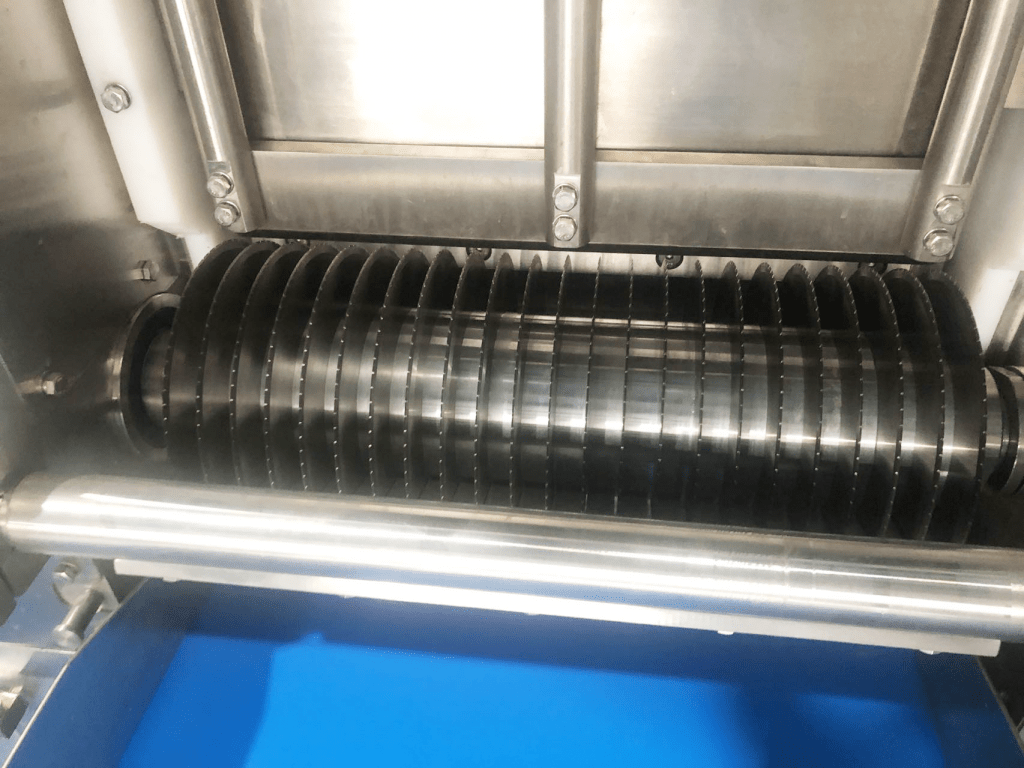

- International advanced cutting motion mode – Four-guide column linear positioning motion cutting structure, After slicing into strips, the strips are cut into cubes by the round cutter.

- Advanced feeding structure – the upper and lower conveyor belts convey materials, and the contact surface between the upper pressing belt and the material is always kept parallel.

- Flexible disassembly – the feeding plate can be disassembled and cleaned directly by hand.

- Cleaning method – direct cleaning with a water gun.

- Safety Device – Inductive Automatic Circuit Break.

- Use – Frozen meat strips, cubes processing.

Technical Features:

| Material | SUS 304SS |

| Slicing Speed | 27-90 slices/min |

| Dimension | 2580*1130*1740mm |

| Feeding Bin Size | 430(W)*50(H)mm |

| Cutting thickness | Customize |

| Round Blade Diameter | 200mm |

| Slicing Temperature | -10℃ - 0℃ |

| Recommend Sllice Temp | -6℃ - -5℃ |

| Power | 12KW |

| Voltage | 380V,50HZ or Customize |

| Weight | 1700kg |